The EU medical device regulations (MDR and IVDR) refer to the requirements that every medical device must meet as General Safety and Performance Requirements (GSPR).

The previous Medical Device Directive (MDD) referred to the “general requirements”.

Content

On this page, you will find references to relevant articles.

- Examples of General Safety and Performance Requirements

- Proof of the General Safety and Performance Requirements

- Differences between the requirements of the MDR and the MDD

- Support in demonstrating these requirements

1. Examples of General Safety and Performance Requirements

The MDR and IVDR list the General Safety and Performance Requirements in their respective Annexes I. Examples of GSPR are:

Note

The GSPR do not depend on the class of the medical device.

2. Proof of the general requirements

The manufacturers themselves provide proof that the medical devices meet these general requirements as part of a conformity assessment procedure. Depending on this conformity assessment procedure, they have to involve notified bodies.

Manufacturers often use harmonized standards to prove conformity with the General Safety and Performance Requirements.

The MDR and IVDR also require compliance with so-called common specifications.

Tip

As a manufacturer, you must demonstrate conformity precisely and sentence by sentence. You can benefit from our checklists such as the MDR checklist.

3. Differences between MDD and MDR

The MDR and IVDR formulate the requirements more granularly than the MDD respectively the IVD did and have expanded them. In addition, the MDR and IVDR distinguish between the “General Safety and Performance Requirements” (Annex I) and the requirements and their verification in the technical documentation (Annex II).

Compared to the MDD, the MDR also explicitly sets out requirements for:

- IT security

- Devices containing medicinal products

- Devices containing tissues of human or animal origin

- Disposal

- Active implantable devices (which were not in the scope of the MDD)

- Devices intended to be used by lay persons

- Labeling

5. Support

Do you still have questions about the basic requirements for medical devices? Then, benefit from free micro-consulting.

The Johner Institute supports medical device manufacturers,

- to prove the requirements with lean technical documentation,

- to check this evidence before the review by a notified body to avoid problems with “approval,”

- prepare the QM system for audits.

Contact us! The Johner Institut team will be happy to assist you!

On December 16, 2025, the European Commission published its proposal for revising the MDR and IVDR , already titled MDR 2.0 and IVDR 2.0 respectively. But will manufacturers really benefit from it? This article provides the answers.

University institutions in particular regularly publish medical software as open source. This raises doubts as to whether this open-source software counts as a medical device and what regulatory and (product) liability risks are involved. This article provides a quick overview.

Details

Combination products consist of the combination of a medical device and a medicinal product. Since both medical device and medicinal product law could be applicable here, there are some special features that must be taken into account for products of this type. In this article, you learn more about

Details

The correct and precise formulation of the intended purpose of medical devices and in vitro diagnostic medical devices (IVD) is crucial for their successful development and approval. However, even the definitions of terms and the connection between intended purpose and intended use make it difficult to achieve clarity and precision. This article reveals how to…

Details

The IEC 61010 series of standards specifies safety requirements for electrical equipment used for measurement, control, regulation, and laboratory use. The general standard IEC 61010-1 and the particular standards of the IEC 61010-2 series describe the state of the art and thus serve IVD manufacturers as a means of demonstrating compliance with the general safety…

Details

Brexit was completed in January 2021. What was a cause for celebration for some means an additional burden for many – including medical device manufacturers. For manufacturers, it is important to understand which regulatory requirements they will have to fulfill and which transition periods they will benefit from if they want to continue selling their…

Details

Regulation (EU) 2025/327 on the European Health Data Space (EHDS for short) is another European regulation that may affect medical device and IVD manufacturers. This article explains what this regulation requires and what these manufacturers have to do by when, as well as the possible advantages of the EHDS and the EHDS Regulation.

Details

People often talk about the approval of medical devices, even if something else is meant – sometimes a certificate of conformity, sometimes a “clearance,” sometimes a successfully completed conformity assessment procedure. Terms like “MDR approval” are even misleading. This article clarifies what a medical device approval means and when manufacturers need one in the first…

Details

A lot of medical device manufacturers see the international authorization of their device as a potential hazard: the opportunities offered by new markets are offset by hard-to-calculate risks as well as the time and costs required for these authorizations. The five steps presented in this article will help manufacturers to manage these risks better. And this is…

Details

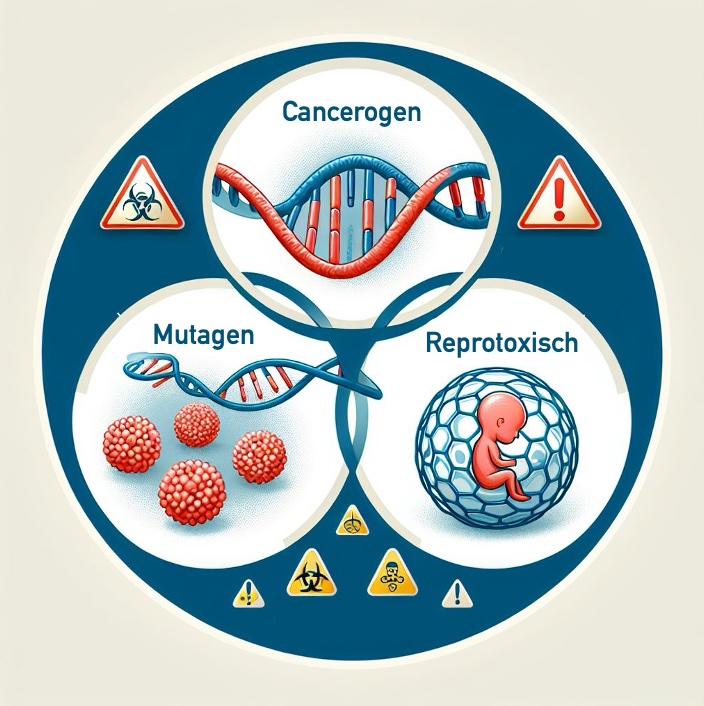

The use of CMR substances is strictly regulated. The MDR also regulates CMR substances and places strict requirements on medical device manufacturers. This article helps to fulfill these requirements.

Details