Companies need to master the digital transformation quickly and successfully. This also applies to medical device manufacturers because, after all, their future depends on it.

Many companies make severe mistakes during this transformation (see section 4). This article provides managers with a quick overview of the possibilities of digital transformation and gives seven tips to make it a success.

This article describes digital transformation using medical device manufacturers as an example. Another article deals with the digital transformation of notified bodies.

1. Digital transformation: Terminology

1.1 Definition

… refers to a technologically triggered and enabled change process that affects all aspects of the company (e.g., devices, processes, organization, business models, culture) with the objective of securing or improving the competitiveness of this company.

Source: Johner Institute

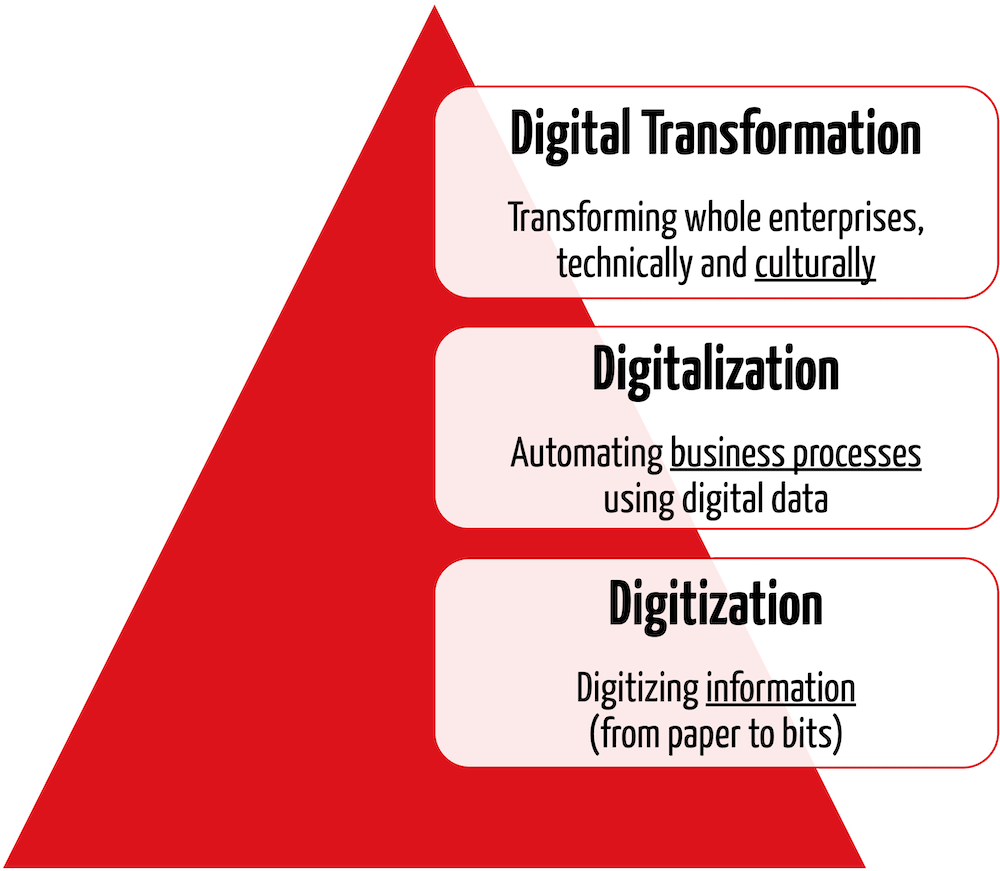

1.2 Differentiation from “digitization” and “digitalization”

Digital transformation should not be confused with “digitization” or “digitalization”.

| Maturity level | Example: Payment | Example: Approval of medical devices |

| Digitization (low) | The customer scans the paper invoice for the accounting department. | The manufacturers scan the signed checklists and test protocols and add them to the technical documentation. |

| Digitalization (medium) | The seller uses software to generate invoices (PDF); the customers use software to pay the invoice. | The manufacturers record the data in a tool and use it to generate PDFs, which they submit to notified bodies or authorities for inspection, e.g., in eStar format. |

| Digital transformation (high) | Customers pay with their smartphones (e.g., in restaurants). | Integrated systems of manufacturers, notified bodies, and authorities automatically and continuously check the conformity of the devices, taking into account the further development of the devices and the state of the art. Documents are no longer exchanged. |

2. Digital transformation based on the example of medical device manufacturers

Digital transformation affects the entire company. Using the example of medical device manufacturers, this chapter describes the effects on:

- Processes

- Collaboration

- Devices

- Identity and culture

2.1 Transformation of processes

All company processes should be evaluated regarding how they benefit from a digital transformation.

| Process (examples) | Transformation (examples) | Benefits (examples) |

| Approval | The integrated systems of manufacturers, notified bodies, and authorities automatically and continuously check the conformity of the devices, taking into account the further development of the devices and the state of the art. Documents are no longer exchanged. | Approval times are falling from months and years to “real time.” The costs involved are imploding. Continuous further development and the adaptation of devices to market requirements become possible. Employees in regulatory affairs are freed from laborious tasks, which makes the jobs more attractive. |

| Post-Market Surveillance | All external and internal sources are continuously and automatically monitored, trends are detected, and measures such as product improvements are initiated directly. | Customer requirements are recognized and problems are resolved more quickly. This increases the conformity, reputation, and safety of the devices and the company. The tedious work involved in market surveillance is eliminated. |

| Development | All design and development outputs are reviewed immediately and automatically. New manufacturing processes allow prototypes to be created quickly. Digital twins of the devices and components enable verification and validation in silico. | Development times and costs shrink to fractions. The risks involved in transferring designs to production are minimized. Both of these factors give manufacturers a decisive competitive advantage. |

Digital transformation is not just about digitalizing existing processes but also about creating new processes and eliminating or merging existing processes.

You can find specific suggestions for individual processes in the article on the digitalization of production, the article on the use of phantoms in development, approval, and market surveillance and the article on simulation (German).

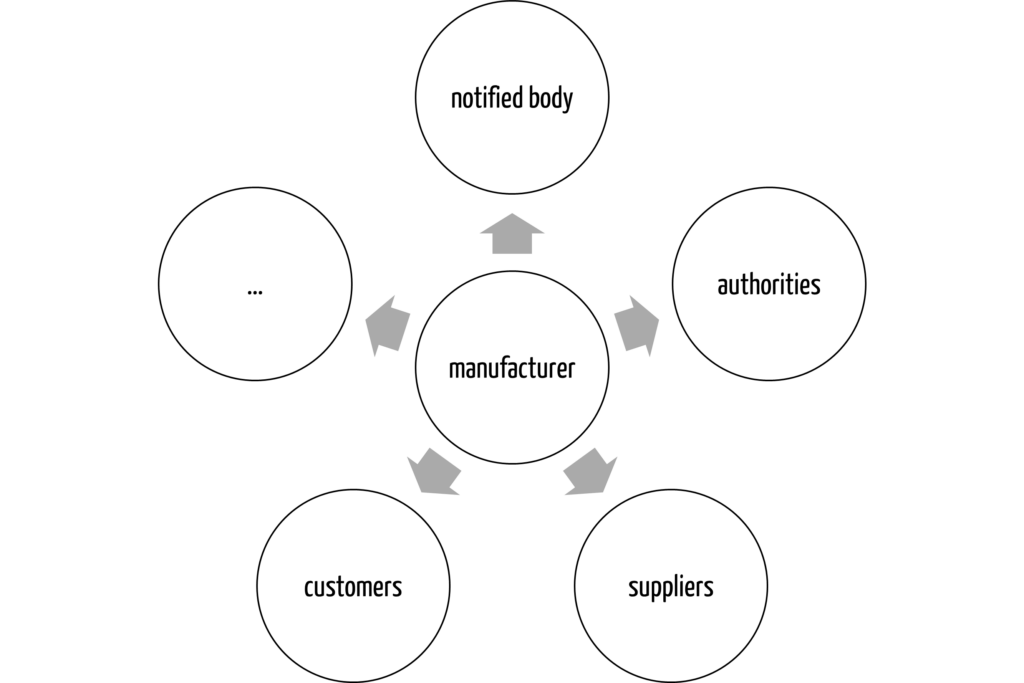

2.2 Transformation of cooperation

The digital transformation should not end at the company’s boundaries. Its potential can only be fully exploited if all organizations involved are integrated (see Fig. 2).

Digital transformation can significantly change collaboration, as the examples in Tab. 3 show.

| Change in cooperation | Example |

| The organizations work on a common data basis or with common IT systems. | Manufacturers and notified bodies in the approval process |

| The organizations are redistributing value creation among themselves. | The component supplier takes over the service of its components installed in the device, from which the supplier continuously receives usage data. Manufacturers become operators of digital apps, for example. |

| Organizations outsource processes | Medical device manufacturers hand over the monitoring of regulations and post-market surveillance to the Johner Institute, which, on the one hand, provides the evaluated data (also via API) and, on the other hand, integrates the manufacturers’ data. |

Digital transformation regularly goes hand in hand with a change in business models.

2.3 Transformation of the devices

The digital transformation does not stop at devices:

| Changes to the product portfolio | Examples |

| New devices | In the future, there will be more diagnostic devices that patients can use directly and without a doctor. Cross-location collaboration between medical experts requires the support of appropriate devices. |

| Transition from devices to systems | Manufacturers should no longer think in terms of devices but in terms of medical processes, solution platforms, and systems to support them. For example, doctors need systems that perform diagnostics, create offers for patients, produce implants directly (e.g., using 3D printing), and ultimately enable doctors to bill patients. |

| More individual devices | Automating many processes (including development and approval) makes it economically feasible to develop devices for smaller patient populations and even individual patients. |

2.4 Transformation of identity and culture

What is probably the most crucial part of the success of digital transformation is the transformation of identity and culture. This manifests itself, for example, in:

- Vision and objectives

- Leadership

- Meetings

- Type and intensity of further training

- Incentivization of employees

- Process models for product development

Are detrimental to a successful transformation:

- Slow or even missing decisions

- Top-down command organization instead of a high degree of freedom

- Inefficient meetings

- Incorrect target metrics such as the number of devices sold (especially if devices are no longer to exist in this form in the future)

- Punishment of failed experiments

3. The necessity of digital transformation

3.1 Ensuring economic efficiency

Personnel and material costs are rising continuously, while the financing of healthcare systems is under increasing pressure. Manufacturers must, therefore, minimize their costs. As the above examples show, this is made possible by digital transformation.

3.2 Ensuring competitiveness and innovative capacity

Economic efficiency is a necessary but not a sufficient condition for manufacturers to be competitive. Their capability to adapt and innovate quickly is also crucial.

The competitiveness of European and especially German manufacturers is suffering, as the regulatory scientists at the Johner Institute were able to show based on official registration data:

- The share of German manufacturers in the German market is continuously decreasing, while the share of Chinese manufacturers is increasing.

- The innovation cycles of German manufacturers are also decreasing, in contrast to those of Chinese manufacturers.

A successful digital transformation

- opens up new business areas,

- accelerates all processes, including development, and

- provides faster and more accurate information on the actual needs of customers.

3.3 Overcoming the shortage of skilled workers

Regulatory requirements and, thus, the need for regulatory experts are constantly growing. At the same time, companies are finding it challenging to recruit these specialists.

Digital transformation helps here by

- eliminating a large proportion of (laborious) tasks and

- making jobs more modern, meaningful, and, therefore, more attractive.

4. Tips for a successful transformation

Many companies make serious mistakes during the transformation:

- They underestimate how urgent and vital this transformation is.

- They confuse “digitalization” with “digital transformation.“

- They believe that the transformation will succeed with the introduction of software.

- They hope to be able to transfer responsibility for this to a Chief Digital Officer.

This is another reason why most transformation projects fail to achieve their objectives. The following tips should help to increase the likelihood of success.

Tip 1: Lead the way with small, targeted experiments

Some companies launch major initiatives with huge budgets and large teams. However, it is a misconception that a big-bang approach and projects planned over the years will lead to success.

Instead, companies need many targeted and rapid experiments with which they can learn. They need an iterative, incremental approach with sprint lengths between 2 and 6 weeks.

These experiments can run simultaneously in different areas.

Tip 2: Be careful with “digital units”

It is expedient to select areas for these experiments that are relevant, capable, and willing to transform. Sometimes, companies even set up their own entities for this purpose.

A culture is then created there that is conducive to transformation. If, at the same time, employees in other areas have the feeling that they are sitting on a sinking ship, this will lead to blockages.

A large German health insurance company has set up such a digital unit. It allows employees from other areas to transfer there to learn and apply what they have learned in their areas.

Tip 3: Ensure management commitment

A digital unit is a clear sign from management that it does not see digital transformation as a buzzword. A genuine commitment from management is a necessary prerequisite (as with all transformation projects).

Commitment means concretely:

- Provide resources (see tip 4)

- Do not shy away from radical changes, even if they affect management itself (e.g., if management levels are eliminated)

- Accept the errors that will inevitably occur with these changes

Tip 4: Provide resources

The resources concern

- the financial resources,

- the necessary experts to strengthen your team,

- the in-house team, which must be continuously empowered,

- the infrastructure, in particular the IT.

Various capabilities and competencies should be bundled in the transformation teams, for example

- Design of agile processes

- Customer research

- Test automation

- Usability

- Communication

- Change management

- IT

Tip 5: Don’t believe that a CDO is enough

Establishing a person such as a Chief Digital Officer (CDO) in the company to drive the digital transformation is helpful. However, the CDO’s options are limited to a staff position without access to the operational areas.

There are alternative and complementary roles to the CDO:

Entrepreneur in Residence: An external expert in digital transformation helps teams interested in the company with implementation or/and becomes part of such a team, teaches best practices and helps develop a showcase.

Accelerator, incubator: This corresponds to the “digital unit” mentioned above, which is freed from the (paralyzing) restrictions (process specifications, meetings) of the rest of the company and is allowed to establish its own culture and concentrate fully on the task at hand.

Fenced startup: Special case of incubators where a concrete device is already ready for development

The book “Das Comeback der Konzerne” – “The Comeback of the Corporations” (German) – shows that corporations are by no means dependent on spin-offs in the form of startups to achieve product-market fit and transform themselves quickly.

Tip 6: Understand the transformation as a never-ending process

Just as the business environment constantly changes, companies must continuously change and thus transform themselves. Digital transformation is a never-ending process.

Tip 7: Always keep an eye on your customers

Change projects involve the great danger of focusing on the company and the changes to its processes, systems, and organizational structures. This must not happen:

All changes must create more value for customers in less time and at a lower cost. All innovations must be geared towards this.

5. Experience of the Johner Institute

The Johner Institute has many decades of experience in the digital transformation of medical device manufacturers, notified bodies, and its own company.

It, therefore, has a precise target image that it has systematically derived:

- Requirements engineering (especially context analyses) with manufacturers and notified bodies

- Decomposition of regulatory requirements and their translation into algorithms

- Deriving the necessary data models

- Development and testing of software applications in the target environments

- Supporting organizations (e.g., medical device manufacturers) in their digital transformation

The Johner Institute offers tried and tested process models and customized software solutions.

Introducing “just” one piece of software usually increases complexity and costs. A digital transformation requires

- a precise transformation plan that defines the objectives and individual steps specifically for the company,

- strict regulatory support because regulatory problems almost always become apparent during the transformation of regulatory processes and should be resolved immediately,

- a didactic concept to involve the company’s employees and consider their workload.

6. Conclusion and summary

Everyone is talking about “digital transformation”. But it is often misunderstood or not implemented consistently. The consequences are declining profitability and competitiveness among manufacturers, as the figures from Germany reveal.

Digital transformation is not a trend that will pass. It is essential for survival.

The Johner Institute supports medical device manufacturers, authorities, and notified bodies in their digital transformation. It also takes over entire processes, such as post-market surveillance.

Get in touch now to talk about how your digital transformation will succeed.

Change history

- 2024-04-24: Introduction and chapter 1 revised (e.g., definition added), introduction for chapter 2 added, numbering changed

- 2023-06-01: Article completely rewritten

I learned alot of things from this blog…thanks