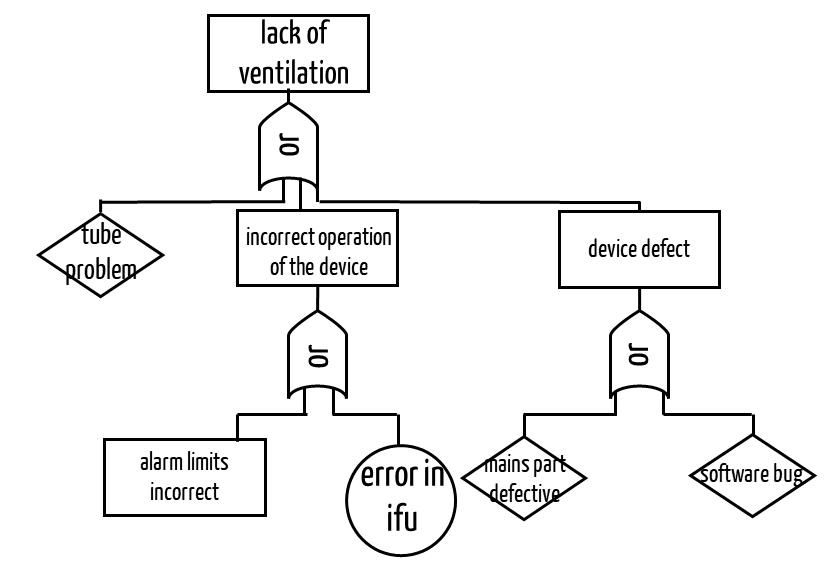

Fault Tree Analysis is a procedure used to search for unknown causes of known effects (in the case of medical devices, harms or hazards). It, therefore, counts as a top-down procedure in risk analysis.

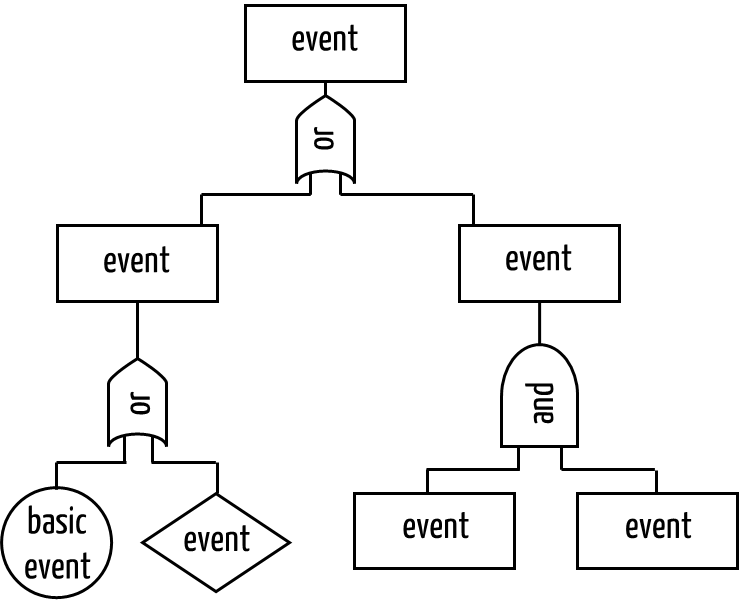

Fault Tree Analysis: Notation

The name Fault Tree Analysis already clarifies how it is represented graphically: As a tree. Both mind maps and Ishikawa (fishbone diagrams) are such tree structures. However, they do not allow the AND and OR links to be displayed.

The notation of FTA diagrams distinguishes:

- Rectangles: Events whereby no distinction is made between intermediate and final events (effect)

- Boolean gates, in particular, AND/OR gates

- Circles: Basic events are events that should not be investigated further. For example, a “force majeure” such as “plane crash on hospital” would not be investigated further.

- Diamonds: These events should be investigated further but are not currently. This is why the diamonds, like circles, are always found as leaves on the tree.

Advantages and disadvantages of the Fault Tree Analysis

Advantages

Only a few medical device manufacturers use Fault Tree Analysis systematically. This procedure offers many advantages:

- Quick overview: The graphical representation makes it possible to get a quick overview of the cause-effect relationships.

- Logical links: While an FMEA searches monocausally for unknown effects (hazards) to known causes, the Fault Tree Analysis shows that a hazard or harm had many causes.

- Level of detail in the analysis: Many manufacturers do not know how granular risks should be described. Risk tables with 1000s of lines are evidence of this. The level of detail can only be determined with the help of a Fault Tree Analysis. More on this below.

- Systematics: You can check a Fault Tree Analysis for completeness by comparing the system components documented in it with the system architecture.

Disadvantages/challenges

- Visualization/modeling tools: A Fault Tree Analysis requires a modeling tool such as VISIO, OmniGraffle, or specialized tools.

- Scope: Especially if there are many hazards, you need a separate fault tree for each.

- Tree structure: A cause can lead to a hazard in several ways, even to several hazards. This means the actual cause-effect relationships are a graph, not a tree. The tree structure, therefore, requires redundant modeling of elements, the synchronization of which can be challenging.

Create a regulatory-compliant risk management file – quickly and audit-proof

With the help of sample templates and videos, you will learn how to create a complete risk management file with all the necessary documents. Check your documents for legal compliance and avoid errors during audits and submissions.

Fault Tree Analysis: Procedure and areas of application

Risk analysis during development

You should use Fault Tree Analysis as a further procedure in addition to Preliminary Hazard Analysis PHA and FMEA during development. The following rules can be useful:

- Composition of the team: Your risk management team includes at least the risk manager, a doctor, and the system architect.

- Number of trees: Create a fault tree for each hazard.

- Level of detail: Search for the preceding events (causes) for each event until one of the following conditions occurs:

- You have arrived at a basic event that cannot be investigated further, for example, because it is a supplier part whose inner workings are unknown, or it makes no sense, as in the case of force majeure.

- The subtree leads to an acceptable risk, e.g., because the probability or severity of the resulting harm is low.

- You can take an action that “cuts off” this subtree or makes it irrelevant.

- Verification: Your Fault Tree Analysis using the following criteria:

- All components of a specific building block level of their system architecture are considered.

- All causes, in particular, all inputs and components or parent components that the FMEA contains, are taken into account.

Fault Tree Analysis in the post-production phase, e.g., for complaint management

The Fault Tree Analysis can also be helpful in the post-production phase:

- All information about risks, such as complaints, BfArM reports, reports to the hotline, etc., should be discussed in your Fault Tree Analysis.

- If you receive an error message, FTA diagrams help describe the causes. This makes the fault tree diagrams the basis of a knowledge database.